Foundry Division

Manufacture of bronze CU3 pieces from 1Kg to 9 Ton of gross weight

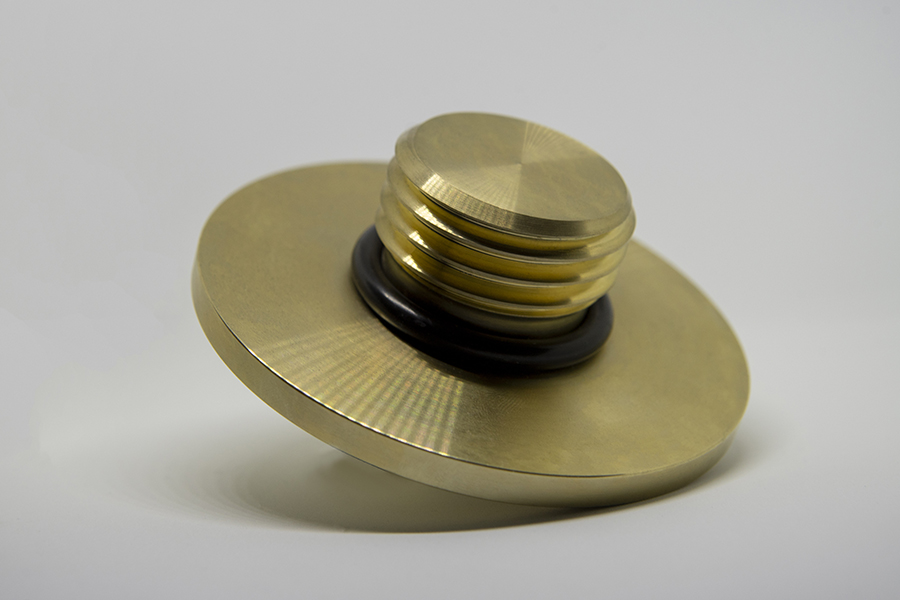

High quality casting

At Weemetal we have created a new business area dedicated to the design, casting and machining of all types of bronze parts, from 1Kg of gross weight to 9Ton. From unique pieces to large production runs with the highest level of quality.

From Weemetal we take care of the entire production phase. From the modeling of the original piece, the sand molding, the casting in different types of alloy and the machining of the final product by CNC machinery

Production system

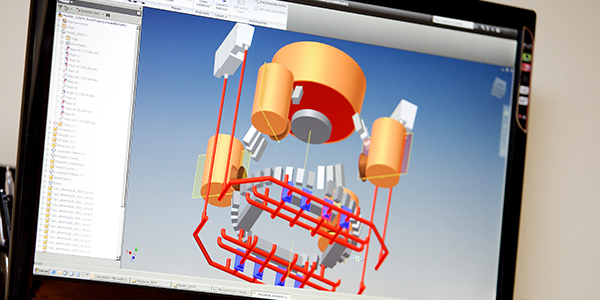

01

Processing of the project in CAD CAM for sending to modeling and generating the casting simulations to find the ideal workflow according to the piece to be manufactured.

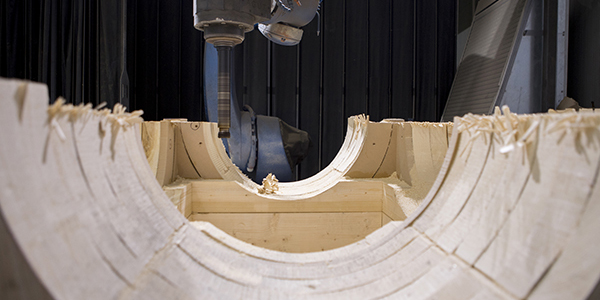

02

The data obtained in the design are sent to modeling, where the most suitable material is chosen and by means of a CNC robot the product is shaped to real size.

03

The model is sent to the foundry where the casting mold is created.

04

By means of CNC machining, the cast iron is shaped to obtain the final product.

05

Processing of the project in CAD CAM for sending to modeling and generating the casting simulations to find the ideal workflow according to the piece to be manufactured.